Sustainable Sailing développe des composites végétaux

La société de R&D et de conseil Sustainable Sailing a mis au point une lame de gouvernail composite biosourcée à 75 %, qui a été approuvée pour une utilisation dans la classe Europe Dinghy. L'alternative nouvellement développée à la fibre de verre pourrait réduire considérablement l'empreinte carbone de l'industrie nautique.

La résine et la mousse utilisées pour construire les coques de bateaux typiques sont dérivées du pétrole, qui a un énorme impact sur le climat. De plus, la fibre de verre nécessite de grandes quantités d'énergie pour sa production. La grande majorité des bateaux sont construits autour d'une âme en mousse, recouverte de fibre de verre renforcée par de la résine. Cela a abouti à des bateaux résistants, faciles à réparer et solides qui peuvent durer extrêmement longtemps, mais avec une énorme empreinte carbone à construire et à entretenir, et aucune voie de recyclage claire à la fin de leur vie.

En combinant les avancées techniques avec une technologie qui remplace un grand pourcentage des composants dérivés du pétrole brut, Sustainable Sailing , basée au Royaume-Uni, affirme avoir été en mesure de construire des composants à 75 % biosourcés.

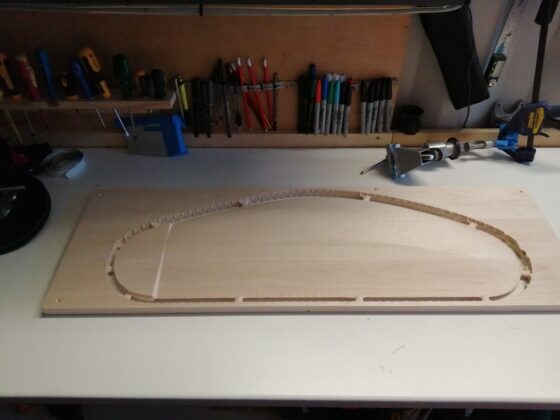

L'entreprise affirme qu'elle s'est concentrée sur les technologies construites à partir de déchets de bois, qui ont été traités de manière à pouvoir être utilisés à la place de la fibre de verre comme renfort dans le composite. Celui-ci est ensuite combiné avec une résine, dont une grande partie de ses matières premières a été remplacée par des alternatives biosourcées, tout en réduisant la quantité de résine utilisée. Cela devrait entraîner une réduction spectaculaire de l'empreinte carbone des composants, tout en maintenant ou en améliorant le profil de performance des composants.

Sustainable Sailing est l'une des rares entreprises à avoir construit avec succès des composants utilisant des fibres et des résines végétales, qui sont utilisées de manière compétitive.

Le directeur fondateur de Sustainable Sailing, Joe Penhaul Smith, déclare : « En nous concentrant sur les dériveurs existants comme preuve de concept pour la technologie et en ciblant les composants plutôt que les bateaux complets, nous avons pu itérer rapidement les conceptions et les technologies à un coût minimal. Cela signifie que les Chlorofoils sont désormais disponibles à l'achat par les marins du dériveur Europe, sans se ruiner.

Les bateaux sont disponibles à l'achat et ont maintenant été approuvés pour une utilisation dans tous les événements de course au Royaume-Uni, avec trois chlorofoils déjà utilisés sur le circuit de course de dériveur en Europe au Royaume-Uni.

Luke Lazell, constructeur de bateaux et pilier de la classe Europe, teste les prototypes depuis le début de l'année. Il dit: "La lame a fière allure, se sent bien et a fait ses preuves dans des conditions venteuses et ondulées, mais vient avec les progrès des nouveaux matériaux et de la durabilité."

Sustainable Sailing développe actuellement cette technologie pour construire une gamme plus large de chlorofoils pour l'Europe ainsi que d'autres classes de dériveurs. Cette technologie apportera également une amélioration spectaculaire de l'empreinte carbone de tous les composites marins.